Customer Requirements:

Hunan Yuneng is a leading supplier of lithium iron phosphate cathode materials, ranking first nationwide in 2022. By the end of 2022, its lithium iron phosphate production capacity reached 348,000 tons. In August 2022, Hunan Yuneng planned to build four new grinding production lines and chose HKZN as the equipment supplier. Each line will have a processing capacity of 3,705 kg per hour, reaching an annual production capacity of 80,000 tons.

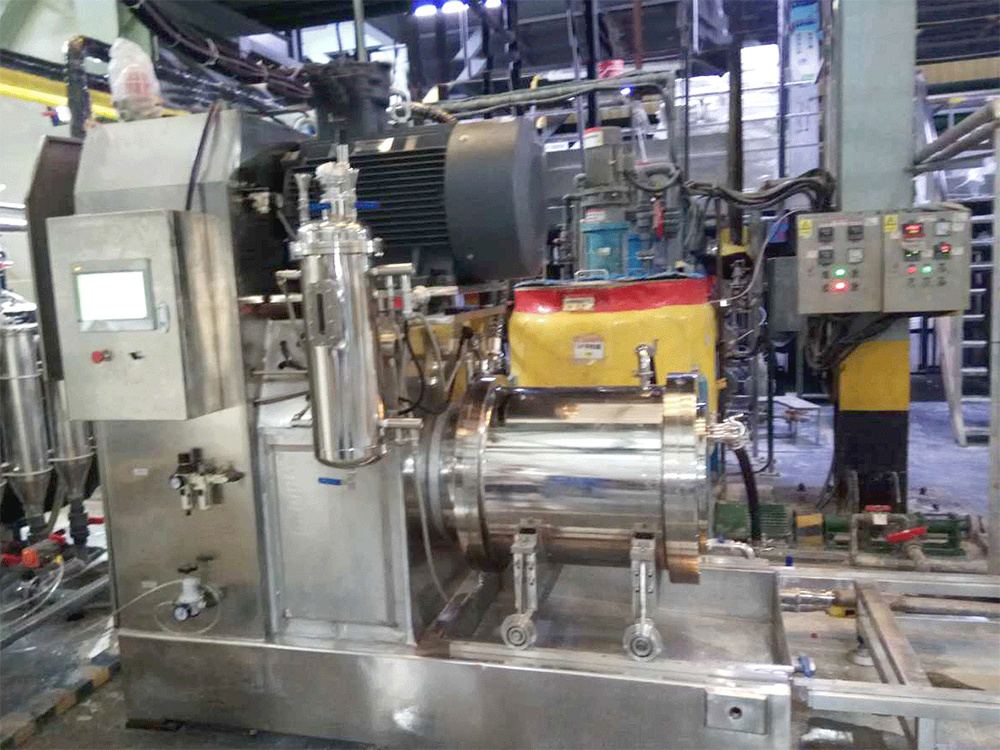

HKZN’s Solution:

The production line includes automatic feeding system, dispersing system, and grinding system. During the automatic feeding stage, three materials are mixed. The grinding system includes three stages, primary grinding, coarse grinding, and fine grinding, and is composed of 9 400L-bead mill with turbine rotor and rotative separation screen on the shaft.Totally 36 units of bead mill are installed in 4 grinding systems.

Project Results:

1. The feed particle size is <1 mm. After coarse grinding and fine grinding, the particle sizes reach 1-2 microns and 350-450 nanometers respectively.

2. Highly viscous materials can be processed, with a solids content of up to 40%.

3. The increase in magnetic foreign matter in the finished product is ≤10 particles per 37 kg.

4. 18 cans of material can be processed daily, with each can containing 5 tons of dry powder.