In the second half of 2025, a leading Chinese new energy battery manufacturer (whose name cannot be disclosed on the website due to confidentiality agreements) invested in building a factory in Indonesia. Following a successful collaboration with HKZN in China, the manufacturer signed a supply contract with HKZN in early October. However, it was subsequently notified that its new energy battery production equipment might be subject to export restrictions in early November.

Due to the tight schedule, HKZN’s newly commissioned intelligent factory in Xiangyang, Hubei Province, leveraged its rapid delivery capabilities. In just one month, HKZN completed the manufacturing of 30 1000LDSR bead mills (Nano Bead Mill with Pin Rotor and PMSM Motor). The equipment was successfully loaded and shipped to the port at the end of October.

This shipment to Indonesia features our star product meticulously crafted for the global new energy market–the 1000L bead mill. With its high capacity, high efficiency, and stable operation, it is undoubtedly a heavyweight in the industrial grinding field!

Powerful and Energy-Efficient: Equipped with a 630kW heavy-duty hollow permanent magnet direct drive motor, and using 0.3-1.0mm grinding media, it adopts a classic energy-saving design, is easy to maintain, and easily meets high-capacity production demands.

Stable Output and Continuous Operation: Optimized static tail-end discharge structure, combined with a patented high-frequency vibration device, completely eliminates traditional material blockage problems, ensuring continuous and stable production and significantly improving production efficiency.

Intelligent temperature control, durable and long-lasting: An external water flow guide and coil-circulating water cooling system effectively reduces temperature, ensuring reliable material temperature, protecting core components, and extending service life!

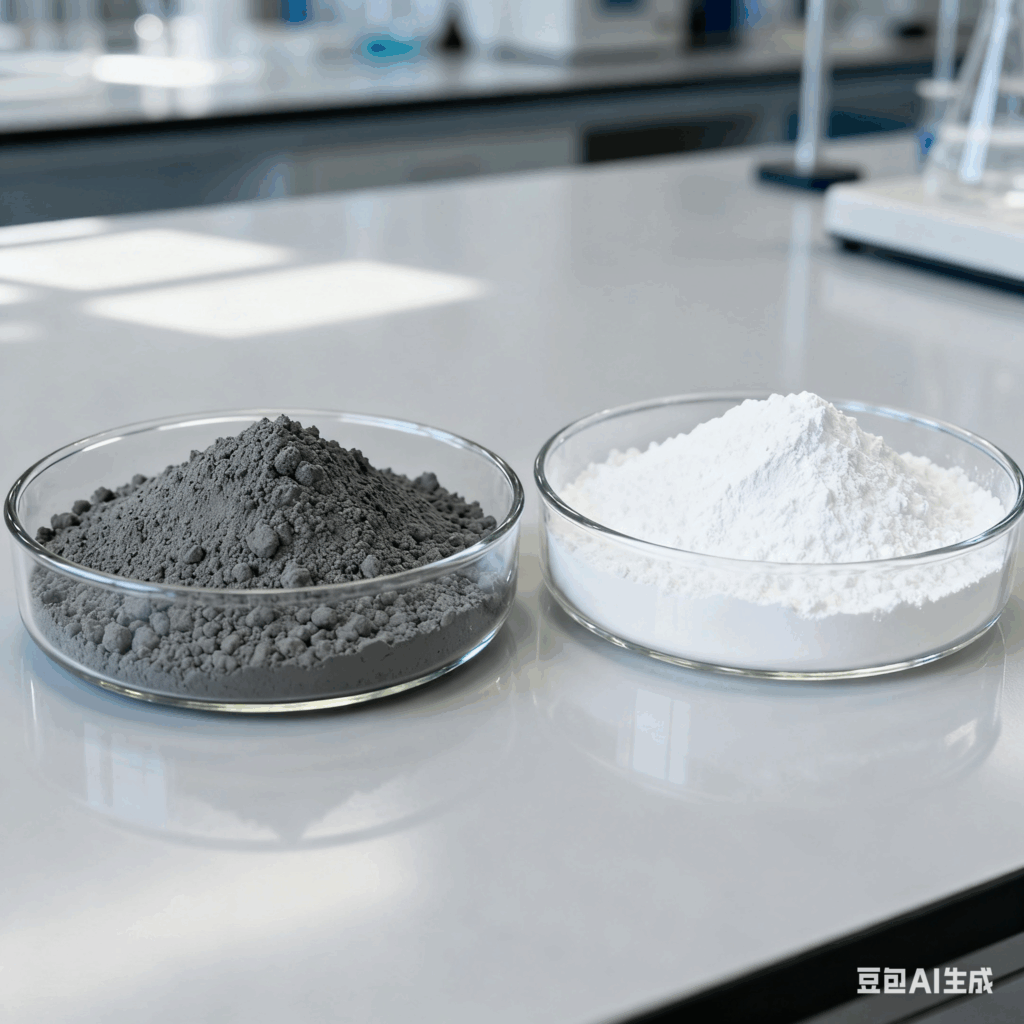

Fine grinding, cost optimization: The output particle size is precisely controlled between 300nm and 1μm, perfectly suited for new energy cathode materials and other fields, achieving the optimal balance between grinding particle size and energy consumption, effectively reducing overall costs for customers.