Customer demands:

ECOPRO BM is a leading global manufacturer of high-nickel cathode materials for lithium-ion batteries. The company specializes in the research, development, production, and sales of core materials for electric vehicle power batteries and is a key player in the new energy industry chain in South Korea and globally.

In 202, ECOPRO BM planed to build a grinding line with an annual output of 3,000 tons of lithium iron phosphate (LFP) battery cathode material.

HKZN’s solution:

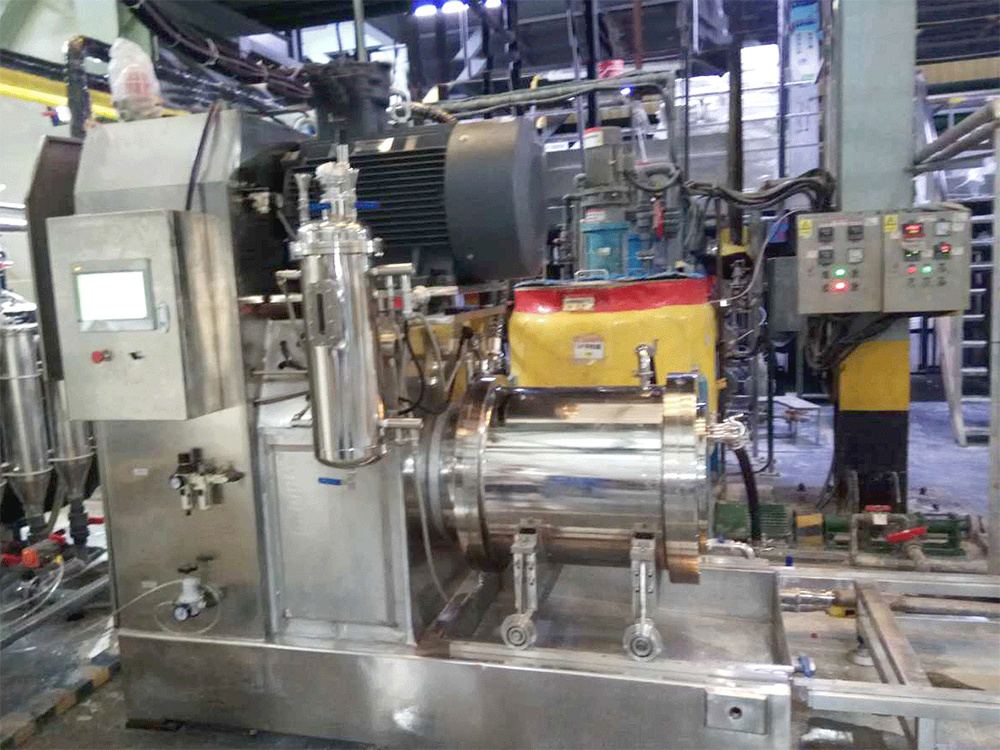

HKZN delivered XX sets of XXXX bead mill to ECOPRO

During processing, the material temperature is ≤45°C and the pressure is <0.3MPa.

The increase in magnetic foreign matter is less than 100ppm, the solids content is 40%-45%, and the particle size D50 is 0.35-0.4μm.

Solution Highlights:

1. Pressure control is crucial. A typical medium pressure setting of 0.3 MPa is used. Special attention must be paid to ensuring that the chamber pressure does not exceed the mechanical seal tank pressure. Otherwise, material may leak into the shaft seal chamber, causing leakage or damage to the mechanical seal. The equipment was configured with a feed pipe specifically for this customer, enabling immediate operation upon startup. A pressure transmitter is installed at the grinding tank feed end to provide overload protection and monitor operating conditions.

2. To meet the customer’s high safety requirements, the control cabinet is equipped with a touch screen, a three-color alarm light, emergency stop, mute, alarm cancellation, and manual/automatic selector buttons and knobs. The on-site operation panel has an IP54 protection rating and above, while the control cabinet has an IP51 protection rating and above.

- High-level intelligence.

In-process material temperature monitoring and over-temperature alarms are implemented.

The inlet pipes for materials coming into contact with shielding gas, air discs, and other gases are equipped with one-way solenoid valves.

Equipment fault alarm information and fault location are displayed on the touch screen, and fault data can be recorded and exported.

The equipment has a status display that automatically displays the equipment’s operating, waiting for material, and shutdown status based on actual operation, and generates equipment operating data tables.

The number of valve and cylinder cycles is recorded.

The operating hours of all motors are recorded, providing automatic maintenance reminders.

Configuration interface design requirements: Configuration conditions can be intuitively viewed within the configuration interface.

Production metering and process data are recorded and exported as reports.

Intelligent data exchange:Equipment power data, motor current and speed data, alarm data, and metering data are transmitted to the PLC, displayed on the touch screen, and generated into reports that can be exported (with timely alarms if they deviate from the design values). All on-site Modbus RTU devices exchange data with the PLC via the CC-Link IE protocol.

The equipment was successfully delivered in mid-2024. This project is the largest localized test line in South Korea and a key milestone project in South Korea’s LFP industry. The project is in normal use after no-load and load tests. It also opens up the sales market for HKZN equipment in South Korea and wins the trust of peer customers.