Customer demand:

Although BYD is a world-renowned new energy vehicle manufacturer, its roots lie in battery production. Starting with battery technology in 1995, BYD has gradually developed into a leading global battery manufacturer, with products spanning consumer electronics and new energy vehicles. Its independently developed lithium iron phosphate “blade batteries” are widely recognized for their high safety and long lifespan, helping electric vehicles overcome bottlenecks in range and safety. Today, BYD not only supplies batteries for its own models but also to other automakers, continuously driving the global energy transition and highlighting its important position in the battery industry.

In March 2018, BYD planned to build four new lithium iron phosphate grinding production lines in Qinghai Province and selected HKZN as the supplier for the production lines. Each production line has a processing capacity of 15 tons per hour and an annual production capacity of 15,000 tons.

HKZN’s Solution:

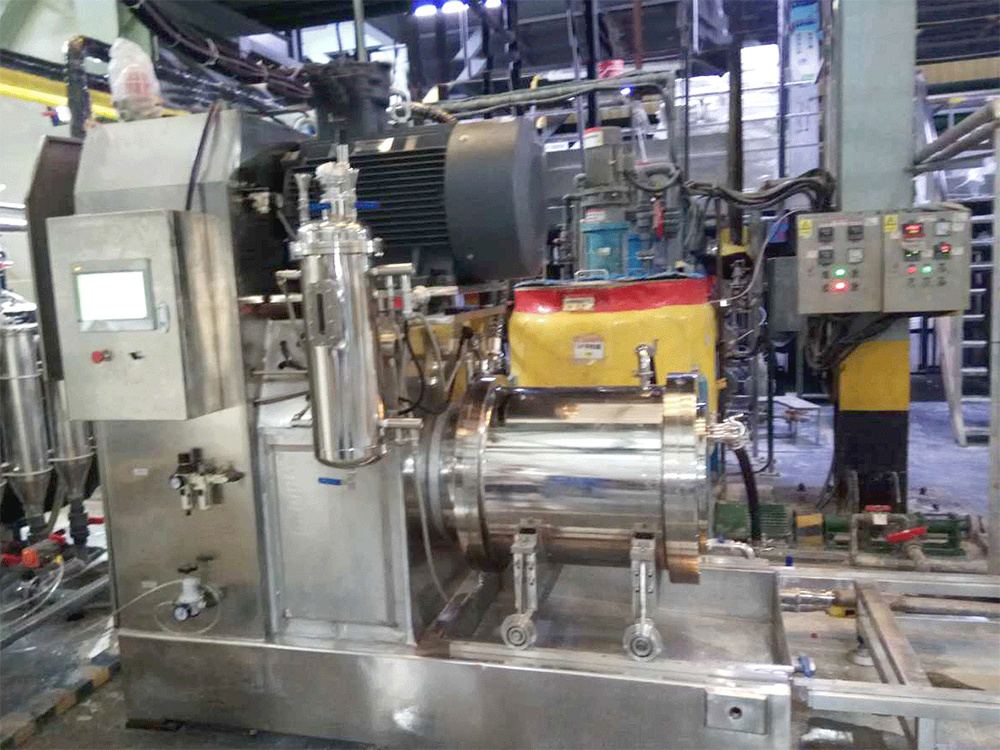

The production line includes an automatic feeding system, a dispersion system and a grinding system.

In the automatic feeding stage, three materials are mixed.

There are two stages in grinding: coarse grinding and fine grinding, consisting of 12 sets of the horizontal nano bead mill with turbine-type rotor and rotative screen on the central shaft. The grinding chamber is 150L.

Project effects

Grinding System:

Material temperature ≤ 45°C

Chamber pressure ≤ 0.3 MPa

Solids content ≥ 35%

Coarse grinding D50 ≤ 1 μm, D90 ≤ 3 μm

Fine grinding D50 ≤ 0.3 μm, D90 ≤ 0.7 μm.

Production Capacity:

Daily production time ≥ 20 hours

Annual production≥ 320 days, daily batch ≥ 20,

Daily production capacity of one production line ≥ 14 tons

Daily production capacity of a complete system ≥ 56 tons

Annual production capacity of a complete system ≥ 19,720 tons.