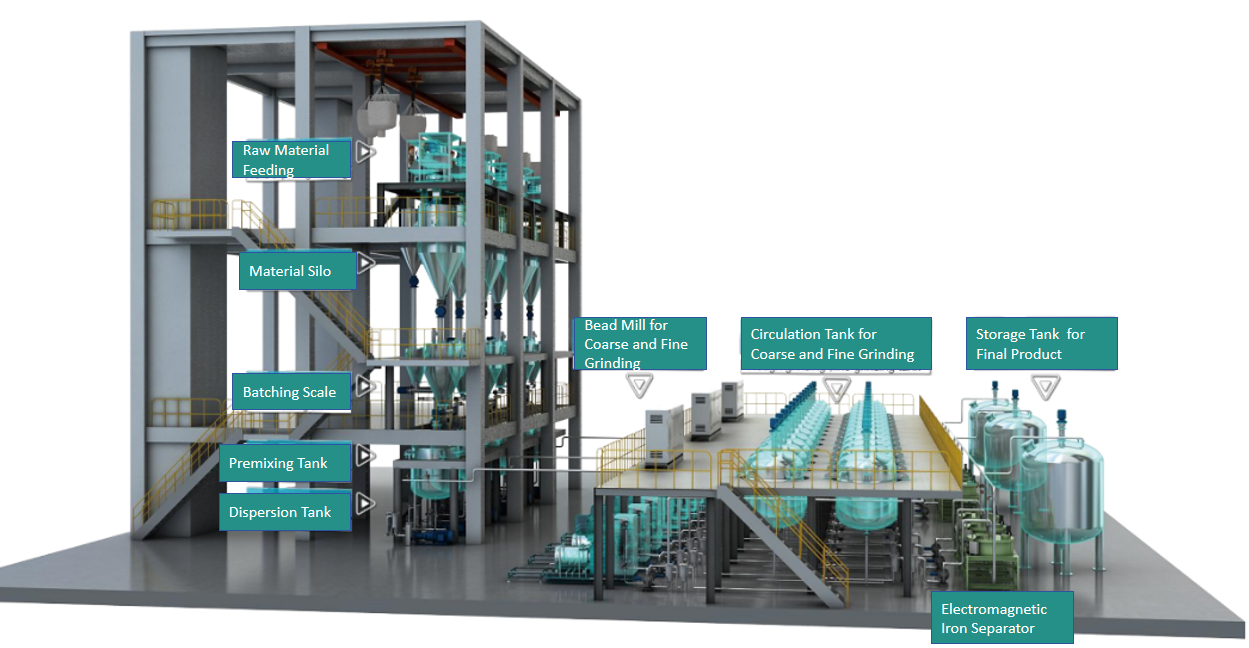

Wet Grinding Process for LFP Slurry Preparation Production Line

This is a typical wet-milling process production line for lithium iron phosphate slurry preparation.

This line is commonly used for cathode slurry preparation. Its goal is to uniformly mix lithium iron phosphate powder, conductive agents (such as SP, CNT), binders (such as PVDF), and solvents (NMP), and then mill them to the fineness and dispersion required for battery production.

It transforms dry powder raw materials into a slurry with specific viscosity, solid content, uniform dispersion, and no metallic impurities, for use in subsequent coating processes.

1. Material Silo

Function: Used to store dry lithium iron phosphate powder supplied from upstream or in bags. It is typically equipped with a dust filter, level gauge, and anti-bridging devices (such as fluidizing plates and vibrators) to ensure stable powder feeding.

Location: At the very beginning of the production line.

2. Metering Silo (or Batching Scale, Weighing Silo)

Function: This is a container with a high-precision weighing sensor. It is used to accurately measure the weight of lithium iron phosphate powder coming from the material silo. It is connected to the material silo via a pneumatic butterfly valve and uses an incremental weighing method to ensure the absolute accuracy of the main ingredient ratio for each batch of slurry.

Key: High precision is fundamental to ensuring battery consistency.

3. Premixing Tank (or High-Speed Disperser)

Function: This is a key piece of equipment for initial mixing. Metered lithium iron phosphate powder, conductive agent, some binder, and most of the solvent (NMP) are added to this tank. The tank is equipped with a high-speed rotating sawtooth dispersion disc that generates strong shearing force at extremely high linear velocities, breaking up large clumps. The powder is initially wetted and mixed with the solvent. Preliminary dispersion is then performed to form a relatively low-viscosity “primary slurry.”

4. Dispersion Tank (or Transfer Tank, Buffer Tank)

Function: Receives the primary slurry from the premixing tank. Its main functions are storage, buffering, and continued slow stirring to prevent slurry sedimentation and ensure a continuous and stable supply to the next grinding process. It is typically connected to a diaphragm pump or screw pump.

5. Coarse Grinding Sand Mill and Coarse Grinding Tank (Circulation Tank)

Function: This is the first stage of grinding. The system consists of a sand mill body and a matching coarse grinding tank.

Process: The slurry is pumped from the bottom of the coarse grinding tank into the coarse grinding sand mill. The inside of the sand mill is filled with grinding media such as zirconia beads. The rotor drives the media to move at high speed, applying strong shearing and collision forces to the particles in the slurry (especially conductive agent agglomerates and large LFP particles), crushing and dispersing them. The ground slurry flows out and returns to the top of the coarse grinding tank, forming a circulation.

Purpose: Primarily solves the problem of nanoscale dispersion of conductive agents and initially breaks down soft agglomerates of LFP, which is the key step in achieving fineness.

6. Fine Grinding Sand Mill and Fine Grinding Tank (Finished Product Tank)

Function: This is the second stage of fine grinding and product finishing. The system structure is similar to that of the coarse grinding mill, but the function is different.

Process: The slurry that has undergone coarse grinding and reached a certain fineness (determined by particle size detection) is transferred to the fine grinding tank. Similarly, the slurry is pumped into a fine grinding mill for circulating grinding.

Purpose: To further homogenize the slurry and ensure that 100% of it passes through a sieve with a specified mesh size.

7. Electromagnetic Iron Separator

Function: Removes metallic impurities; a key device for ensuring battery safety (preventing internal short circuits).

The electromagnetic slurry iron separator generates a high-intensity magnetic field that adsorbs trace amounts of ferromagnetic metal particles that may have been introduced into the slurry during feeding, conveying, and grinding.